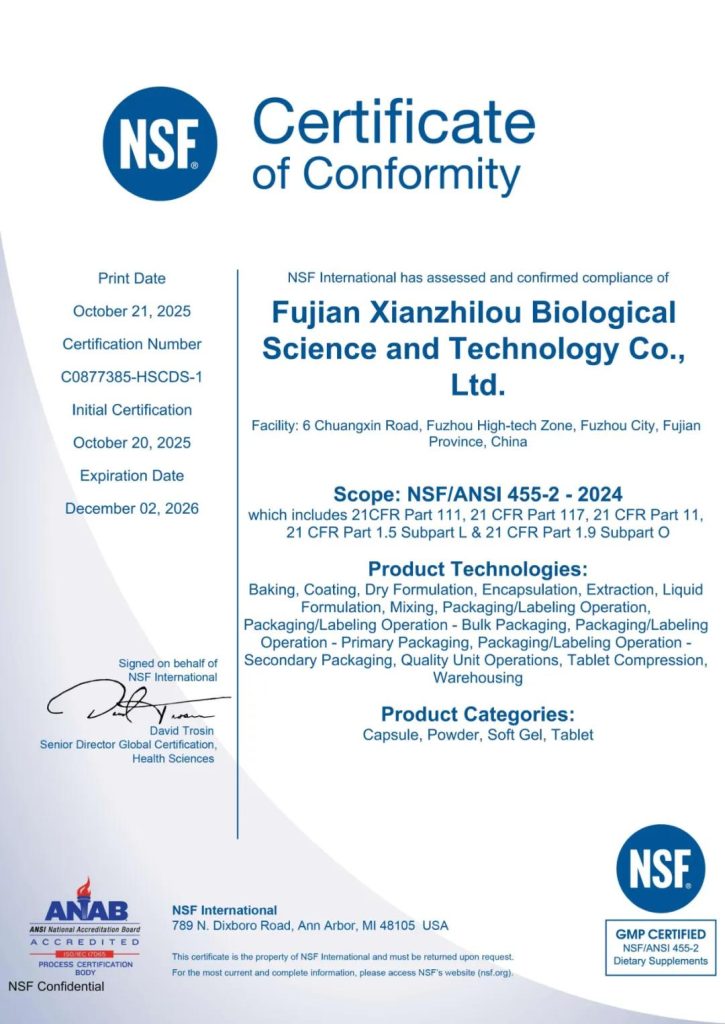

On October 21, 2025, GanoHerb Group officially passed the NSF/ANSI 455 GMP certification, becoming a certified manufacturer that complies with the Good Manufacturing Practice (GMP) standards for dietary supplements in the United States. This internationally authoritative certification signifies that GanoHerb has achieved a globally leading level in its production quality management system, providing strong support for the Group’s accelerated global expansion.

NSF is an independent global organization dedicated to protecting and improving human and planetary health by developing standards and providing world-class testing, inspection, certification, consulting, and digital solutions for the food, agua, health sciences, and consumer goods industries. NSF operates in more than 180 countries and regions worldwide and serves as a World Health Organization (WHO) Collaborating Center for Food Safety, Water Quality, and Medical Device Safety. Together with the American National Standards Institute (ANSI), NSF has developed multiple standards that are recognized as U.S. national standards. Además, NSF certifications are acknowledged by 13 authoritative national and industry organizations, including the U.S. Occupational Safety and Health Administration (OSHA) and the Standards Council of Canada (SCC). NSF also holds several domestic accreditations, including CNAS and CMA/CMAF.

Achieving NSF/ANSI 455 GMP certification verifies that NSF conducts annual audits of GanoHerb Group’s manufacturing facilities for quality and safety, ensuring compliance with the 455 series standards for retailers and the industry’s Good Manufacturing Practices. The NSF GMP mark demonstrates GanoHerb Group’s commitment to consumers, minoristas, and regulators that its certified facilities meet all standard requirements in terms of manufacturing processes, procedures, facilities, and documentation systems.

Passing the NSF GMP certification means that GanoHerb Group’s factories have successfully passed NSF audits in the following aspects, including but not limited to:

· Audits of all facilities involved in the manufacturing, embalaje, warehousing, or distribution of dietary supplements

· Review of quality departments and leadership structures

· Audits of quality control testing procedures for raw materials and finished products

· Inspection of maintenance, upkeep, cleaning, and sanitation programs

· Review of procurement and traceability procedures

· Review of product safety procedures

· Review of training and qualification programs

· Review of product recall and adverse event reporting procedures

Going forward, GanoHerb will continue to increase investment in scientific research, strictly implement its full-chain quality control system, and contribute to the high-quality development of the Reishi health industry.